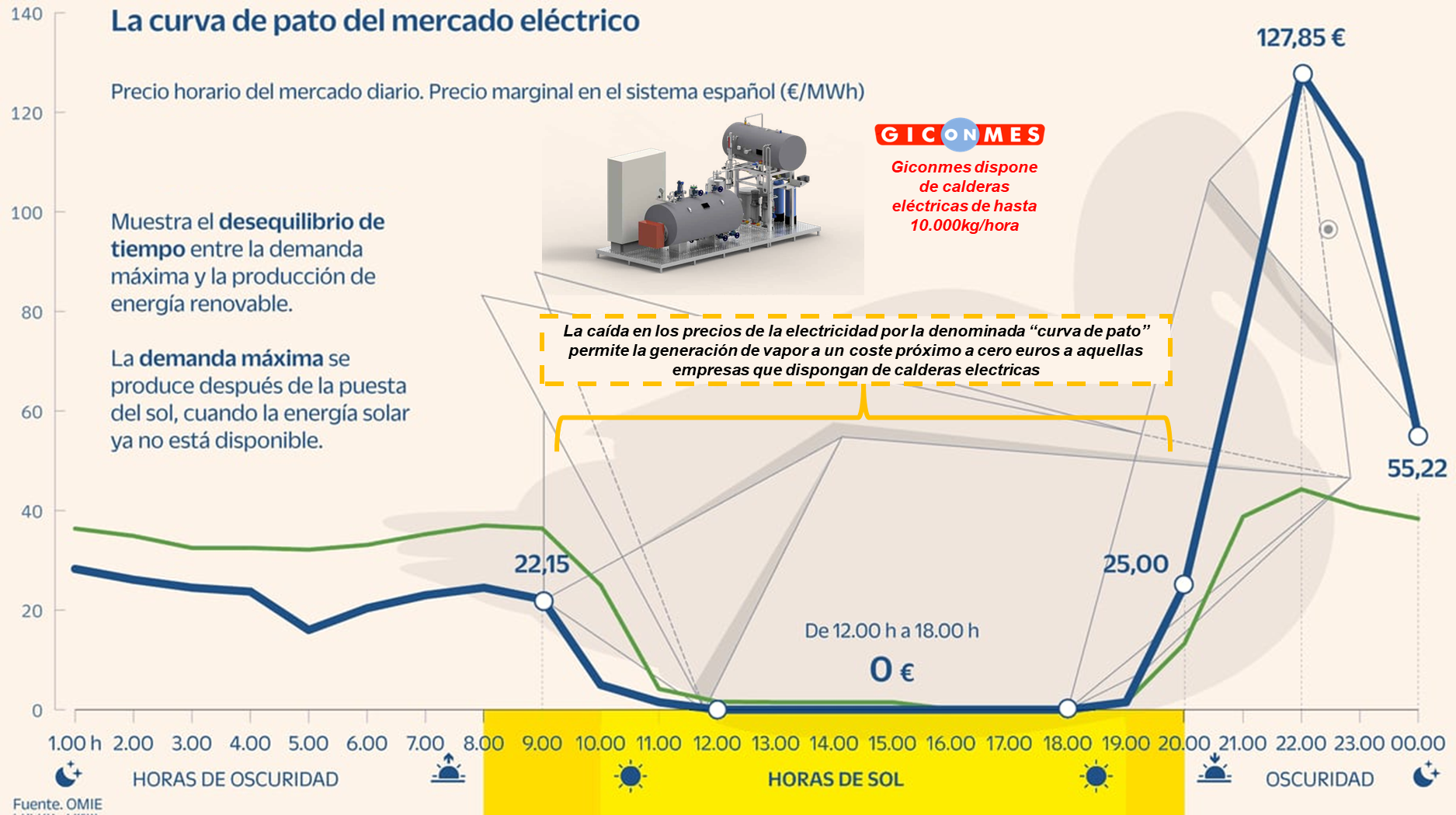

3x Blowdown tanks

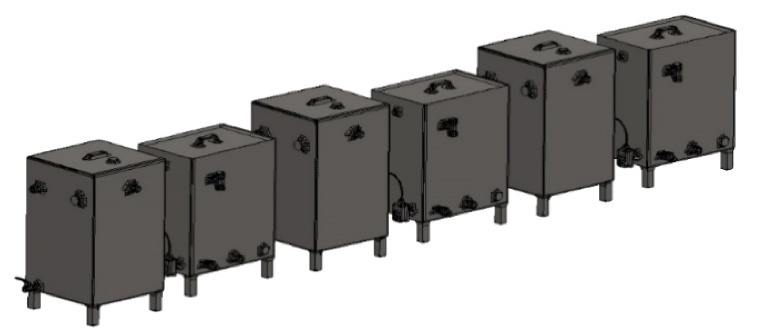

Steam heating system in a container

PS 2

The PS 2 model is a mobile boiler room with the dimensions of a 40-foot shipping container (12.2 meters long, 2.4 meters wide, and 2.6 meters high) custom-built for the purpose.

The containerized steam installation has been designed as a complete system with all necessary components pre-installed at the factory.

Each module is equipped with a PLC, and all three modules are connected to a master PLC located in the main electrical panel. There is the possibility of installing a twin display screen in the control room.

Designed to provide complete steam solutions in a compact manner. The versatility of containerized systems is a great advantage for certain industries.

Container solutions offer a fully integrated and self-contained steam system housed within a container. This innovative design allows for easy transportation, quick installation, and flexible deployment in multiple locations, making it ideal for temporary steam needs, remote areas, or rapid deployment scenarios.

Inside the container, you will find a range of high-quality components that work seamlessly together to provide efficient and reliable steam generation. Inside the container, you will find a range of high-quality components that work seamlessly together to provide efficient and reliable steam generation.

The system is equipped with various safety features, including advanced control systems, pressure control valves, and monitoring systems, ensuring safe and reliable operation at all times.

| Model | NGV-60180 (x6 modules) |

| Voltage (V Hz) | 24 |

| Steam pressure (bar) | 0,3/8,5 |

| Total boiler power (kW): | 180 (x3 modules) |

| Boiler capacity (Liters/UK gallons/US gallons): | 3×60/3×13/3×16 |

| Boiler material | AC / AISI 304 / AISI 316 |

| Pump power (kW): | 3×0,55 |

| Steam outlet height (mm) | 530 – 1070 – 1600 |

| Condensate return height (mm) | 280 – 850 – 1380 |

| Condensate tank capacity (liters/UK gal/US gal) | 160 / 36 /42 |

| Condensate tank capacity (liters/UK gal/US gal) | 1160 x 950 x 1670 |

| Net weight of the boilers (kg/lbs) | 325/716 |

| Power and production | NGV-60180 (x6 modules) |

| Power (kW) | 180 (60+60+60) (x6 modules = 1.0MW) |

| Steam production (kg/h) | 245 (x6 modules = 1.500kg/hour) |

| Heat production (kcal/h) | 155.000 (x6 modules = 0.9m) |

Installation elements

The system consists of three steam boilers (modules) NGV60180 with a combined capacity to produce 1500kg/hour of steam. The installation includes stainless steel condensate recovery tanks and a water treatment system (if necessary).

- 6 x NGV60180

- 6 stainless steel condensate recovery tanks

- 6 blowdown tanks

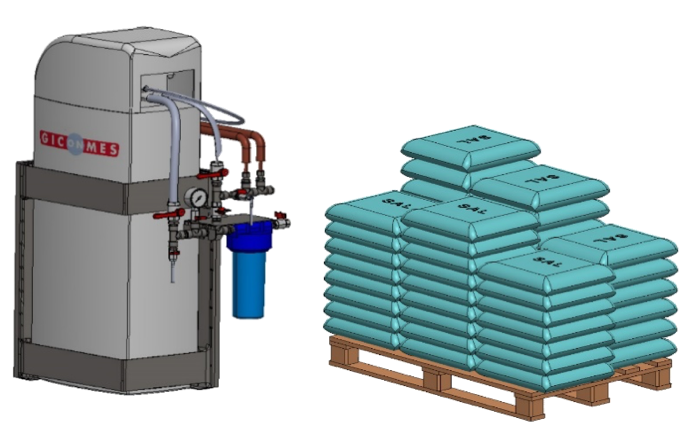

- Water treatment system

- 2 – 2000L water tanks

- Factory testing of the containerized steam installation before shipping

The containers include:

- Fully insulated container walls lined with stainless steel

- Possibility of heating and ventilation according to boiler room requirements

- All components inside the container are pre-wired and ready for service

- Connection points on the exterior walls at agreed positions

- Exterior paint according to customer specifications

Steam generator accessories

Custom-designed accessories for each customer

Optimize operating costs, steam quality, and find solutions to your needs by incorporating the available accessories to your generator. We will be delighted to assist you in selecting the right ones for your requirements!

Industries and Applications

Steam is used in heating, sterilization, or sanitation processes

The engineers at Giconmes have been developing numerous applications based on heat transfer through steam since 1957. You can find examples of our solutions in the following case studies

FAQs

We understand that many questions may arise. Here are some of the most common ones.

There are no emissions other than those produced in the electricity production process. Therefore, they can be neutral depending on the electricity mix. Electric steam boilers are indeed the present and the future.

Absolutely. It is even recommended for achieving maximum efficiency. There is no problem with remote control as long as current regulations are followed.

A steam generator is a pressure vessel that, along with the connected pipe network, is subject to regulatory control and complementary technical instructions, as stated in the regulations published in Royal Decree 809/2021, dated September 21st. The maintenance of an electric steam generator is divided into a part that can be easily carried out by the owner:

- Familiarize yourself with and apply the manufacturer’s instructions regarding the use, safety measures, and maintenance.

- Do not put the installation into service or prevent the operation of pressure equipment if they do not meet the requirements of the regulations

- Maintain at least the following documentation of the pressure equipment while they are installed: Declaration of Conformity, if applicable, manufacturer’s instructions, and, if necessary, installation certificate, along with other supporting documentation (such as Installation Project, record of the last periodic inspection, certifications of equipment repairs or modifications, as well as any other documentation required by the corresponding complementary technical instruction (ITC) of this regulation). For detailed information, please refer to Annex IV of the regulation. This documentation must be made available to the competent authority of the autonomous community and to the companies responsible for maintenance, repair, or periodic inspections

- Use pressure equipment within the operating limits specified by the manufacturer, and withdraw them from service if they no longer meet the necessary safety requirements.

- Perform maintenance on the installations, pressure equipment, safety accessories, and control devices in accordance with the operating conditions and manufacturer’s instructions, and examine them at least once a year

- Arrange for the necessary periodic inspections as stipulated in Article 6 of the regulation.

- Maintain an up-to-date record of pressure equipment belonging to categories I to IV, as defined in RD 709/2015, dated July 24th, or equipment deemed equivalent to these categories according to Article 3.2 of the regulation, as well as their installations.

It is known that by applying heat to water, it transforms into steam at its boiling point under atmospheric pressure. From there, depending on the desired level of steam saturation for its proper application, we may need to increase the pressure in order to achieve higher temperature. To change the temperature and saturation level of steam, it is indeed necessary to modify the pressure.

It is a unit of pressure equivalent to 1 kg/cm2, 0.98 atmospheres, or 14.50 PSI.

Haven't found the answers to your questions?

Please send us a question or download all the information

Quick technical service, with trained professionals and service plans focused on your company

What kind of steam system do you need?

Equipment rental

Reliable, safe equipment with a 5-year warranty.

Enjoy the security of a personalized service

24/7 adapted to your needs.

Do you need a customized solution?

We help you define what type of installation you need

Steam and

Giconmes

Here you will find informative articles about steam technology, its application in industry, and different types of related equipment, as well as the latest trends and developments in this field.