industrial steam installations

Steam installations in industry

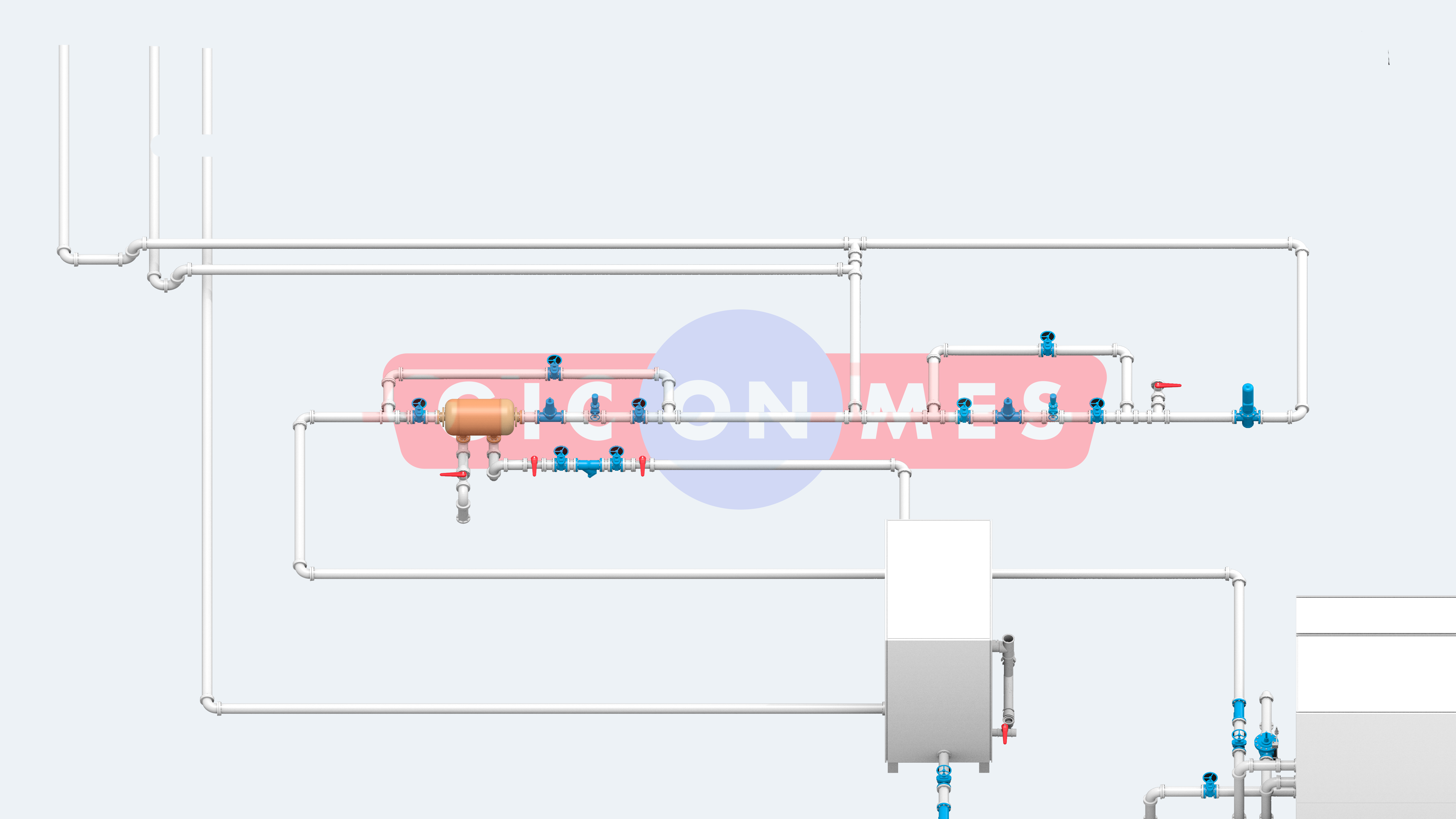

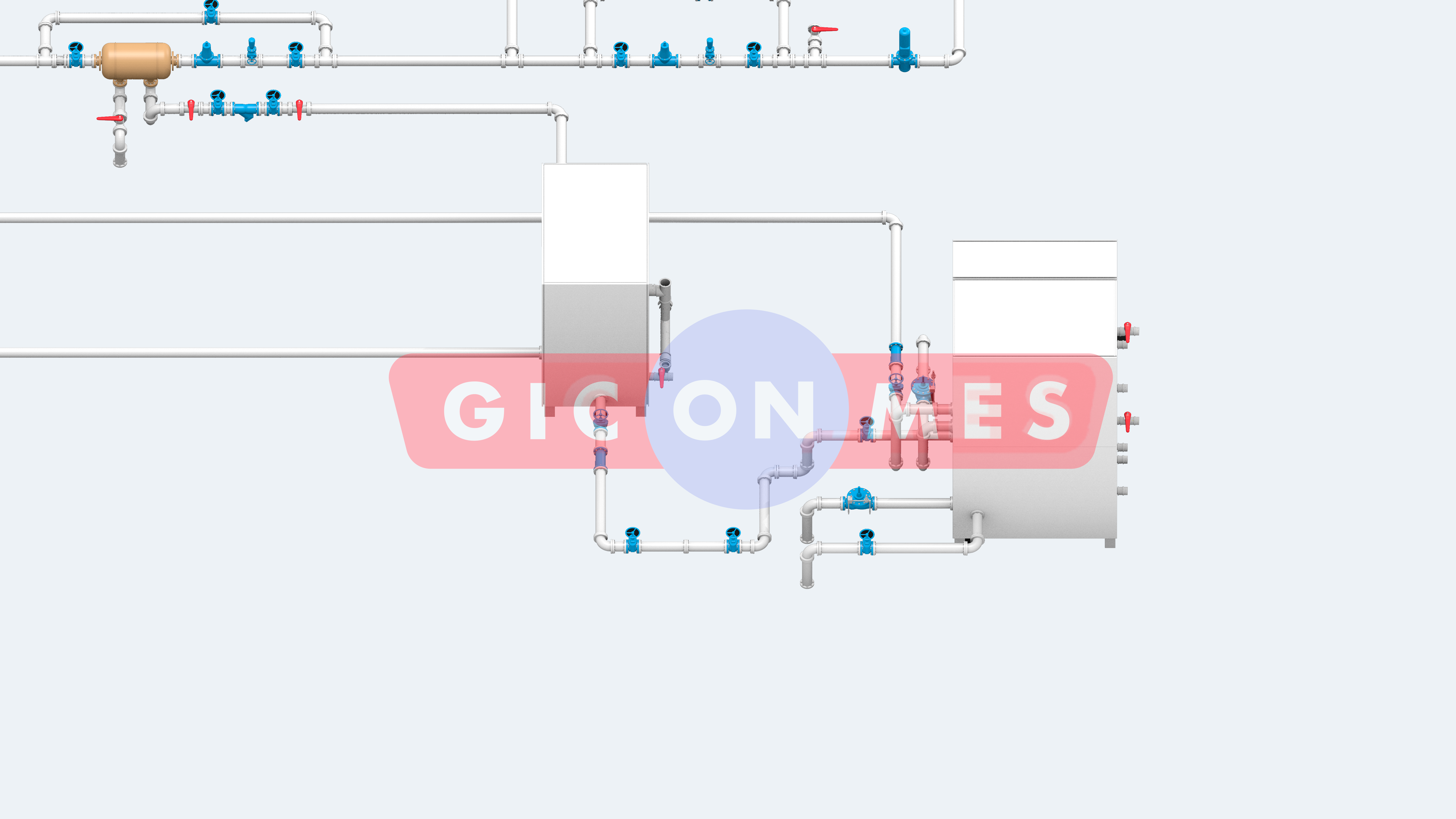

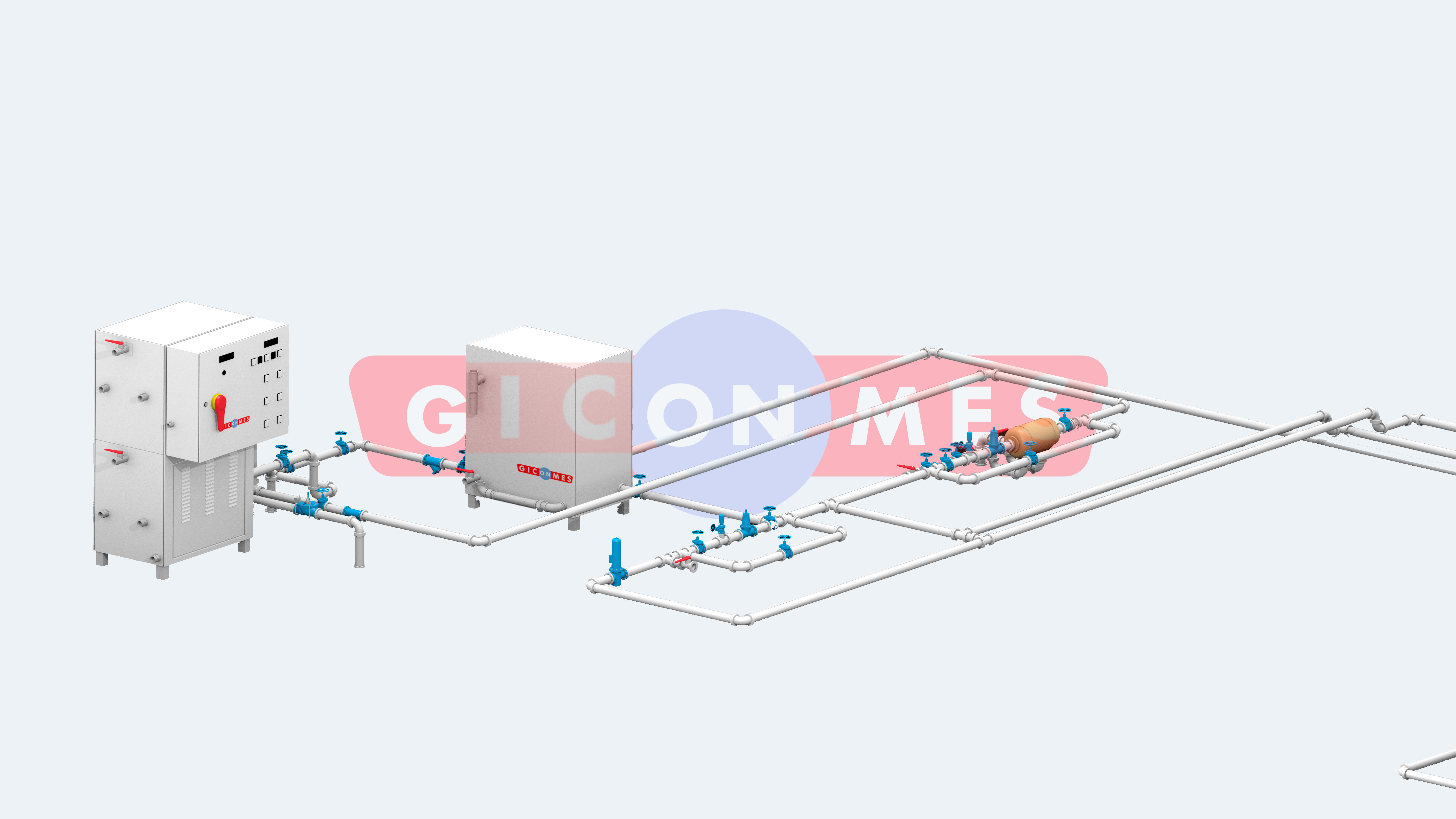

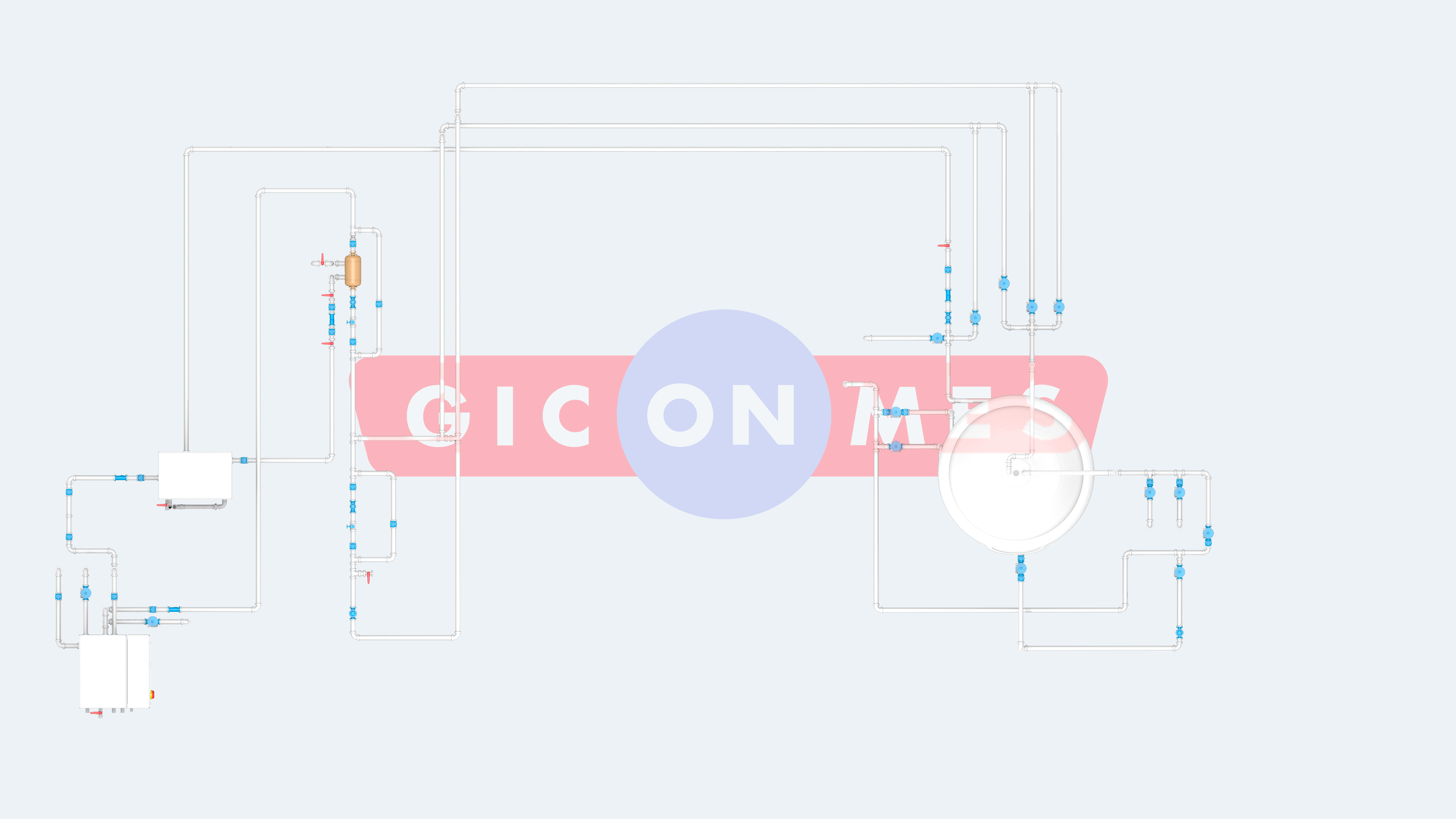

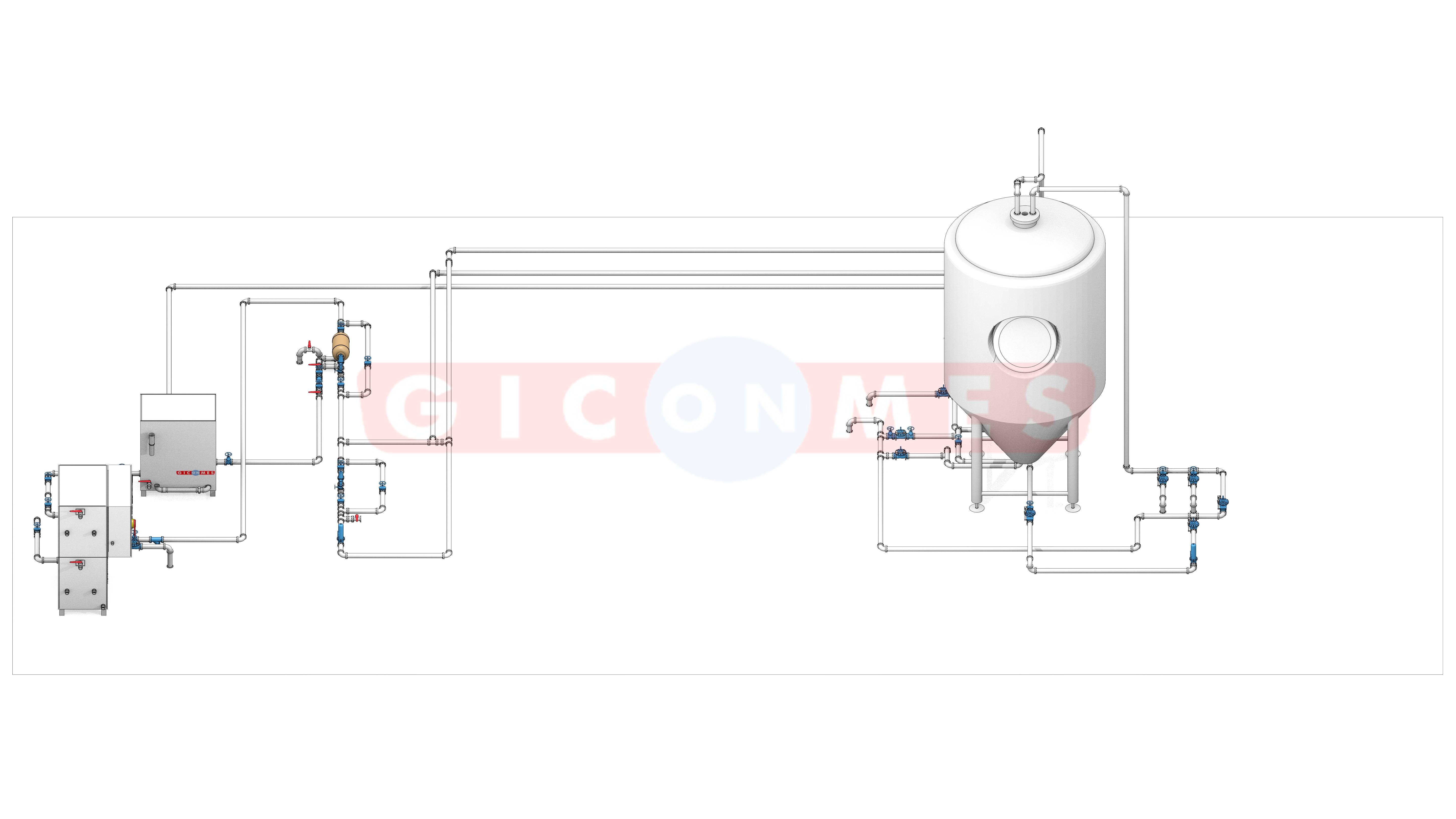

Giconmes is specialized in the design, assembly, commissioning and maintenance of steam installations steam installations in a multitude of industries (e.g.: pharmaceutical, biotechnology, food, etc…). These installations usually include an electric steam boiler, various auxiliary equipment such as condensate tanks or water treatment systems and valve systems to optimize and control the steam.

With our own technical service team or through your own installers, we offer you our know-how to ensure an effective, efficient and turnkey design of your installations.

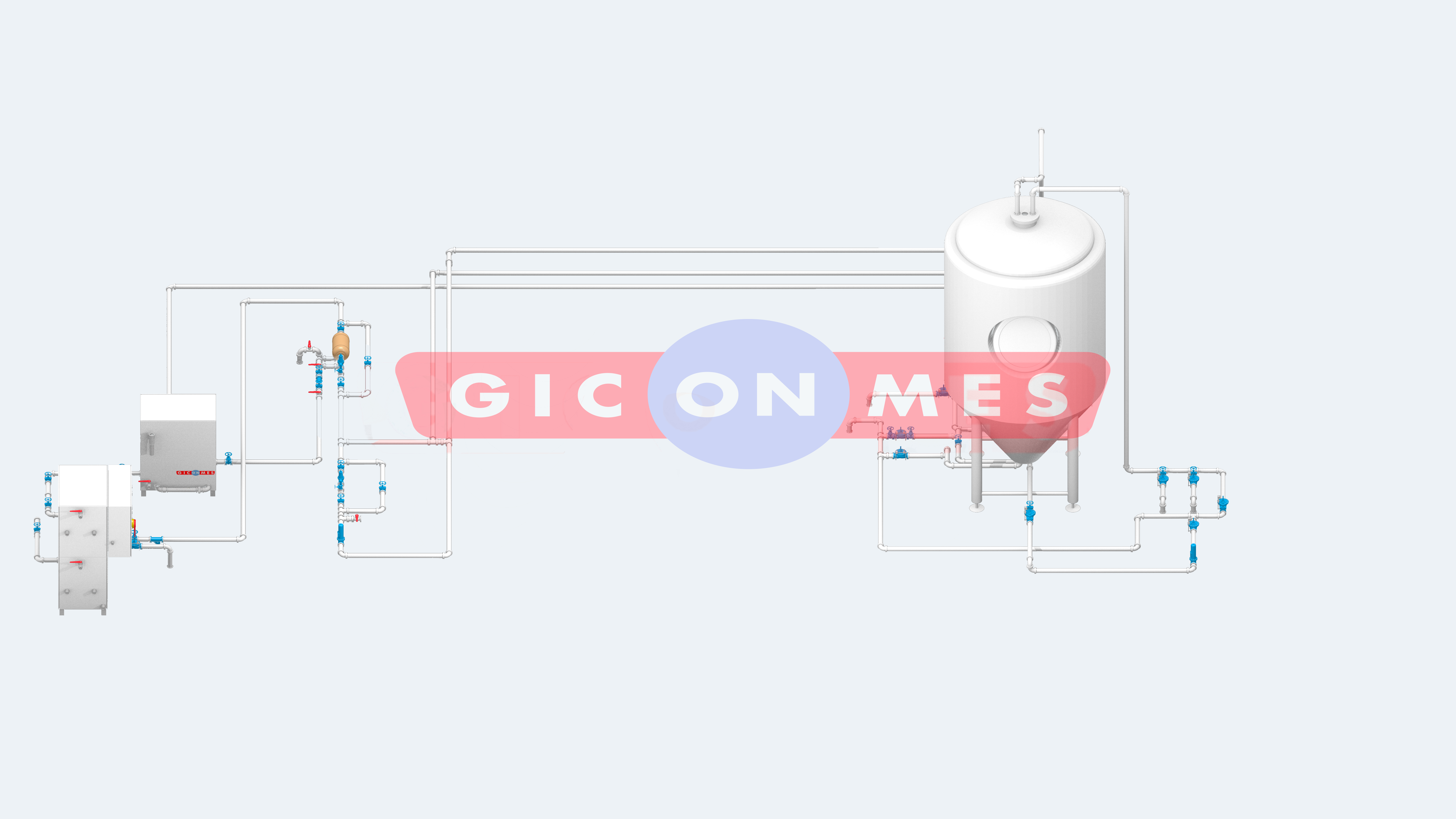

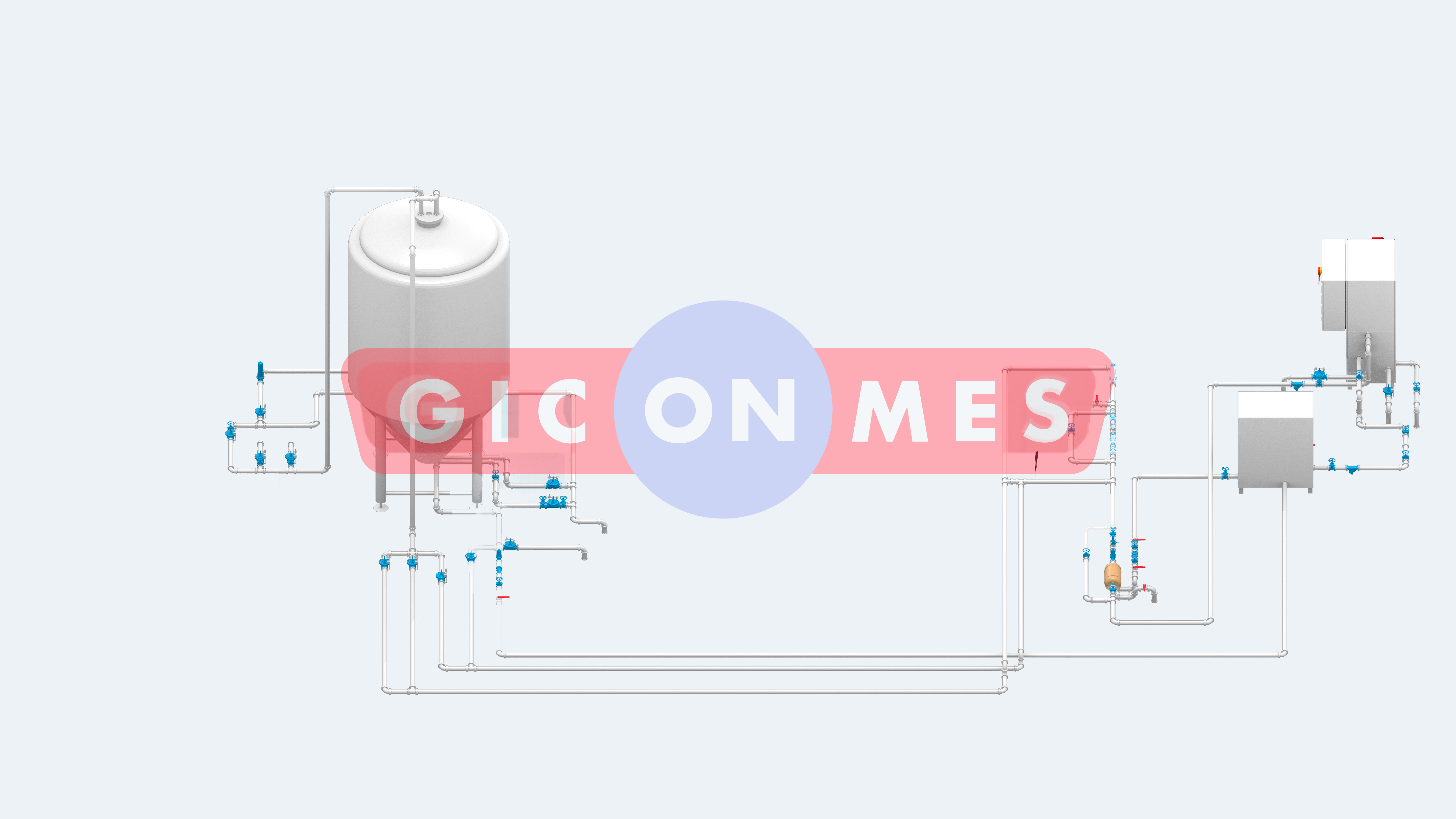

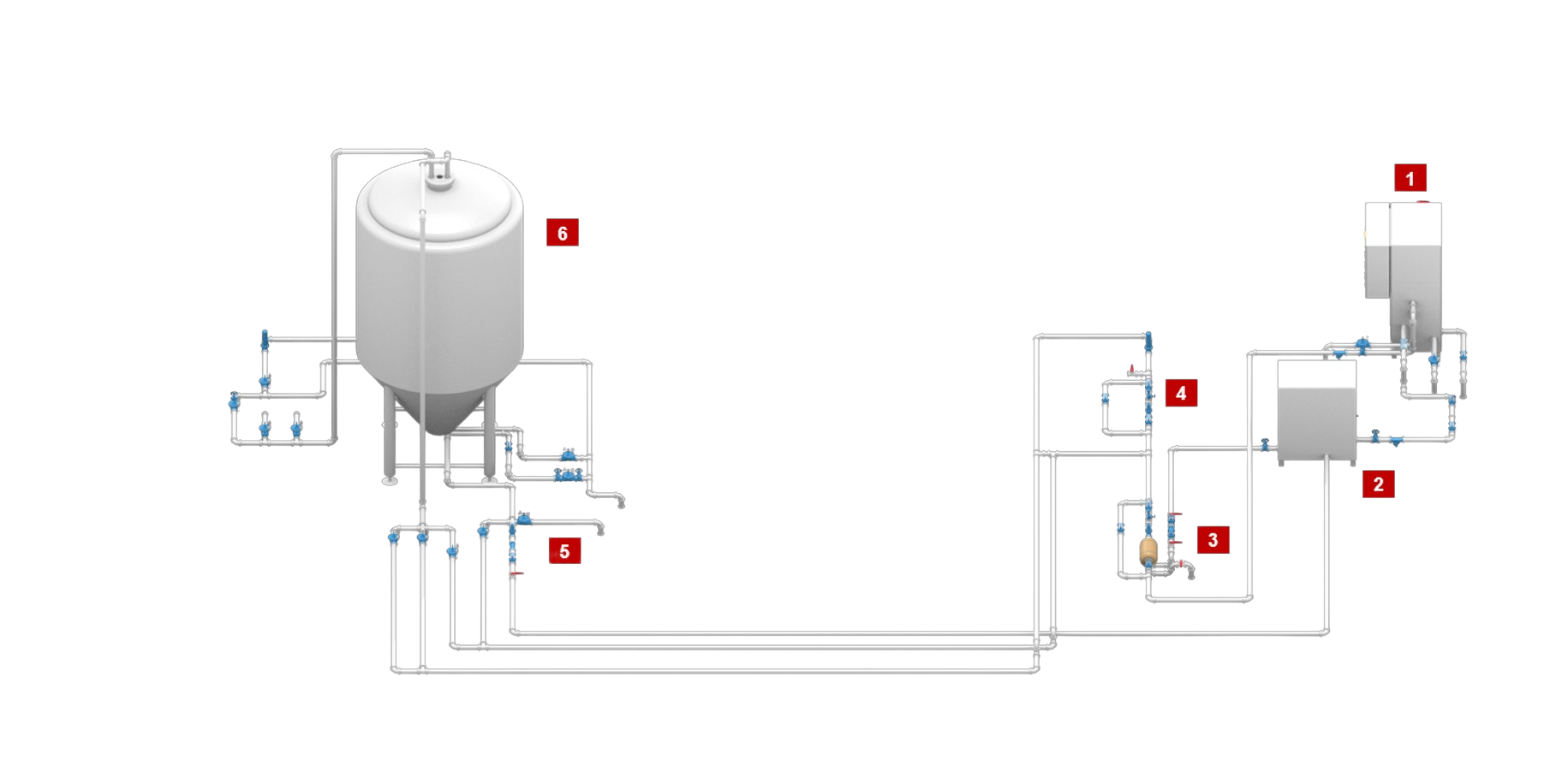

Steam boiler

Steam boiler NGV6060 (60kW) in stainless steel AISI A-316

Includes:

-Manually operated valve

– Filter

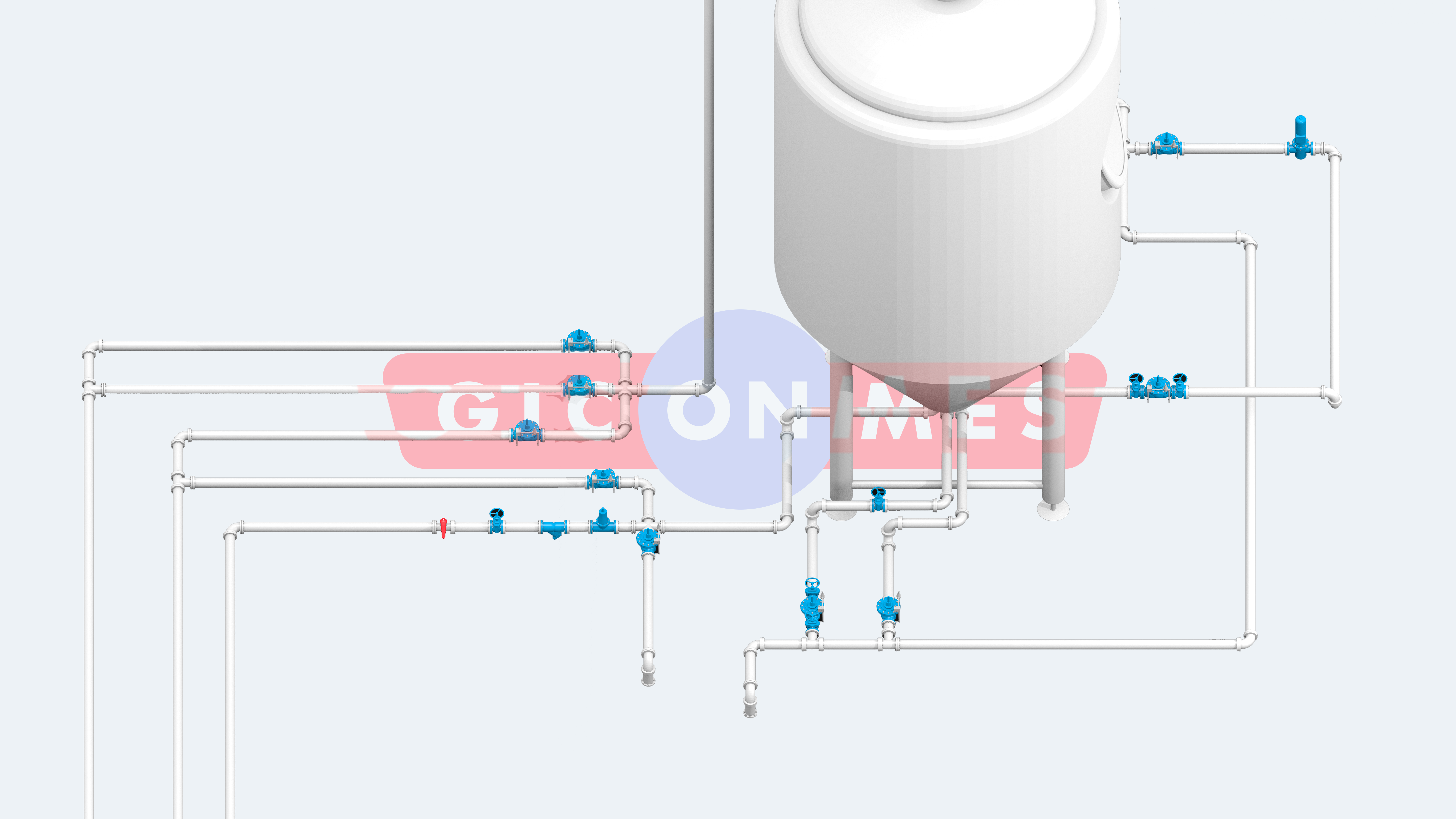

Condensate Tank

Condensate tank made of stainless steel AISI A-316 of 80 liters.

Pressure reducing station (from 7 bar to 3 bar)

– Manually operated valves

– Filters

– Pressure reducing valve

– Manual ball valves

– Condensate boiler

– Thermodynamic purger

Pressure reducing station (from 3 bar to 1 bar) with 5 micron steam filter to obtain culinary steam

– Manually operated valves

– 5-micron filter for culinary steam

– Pressure reducing valve

– Manual ball valves

– Condensate boiler

– Thermodynamic purger

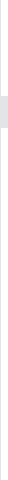

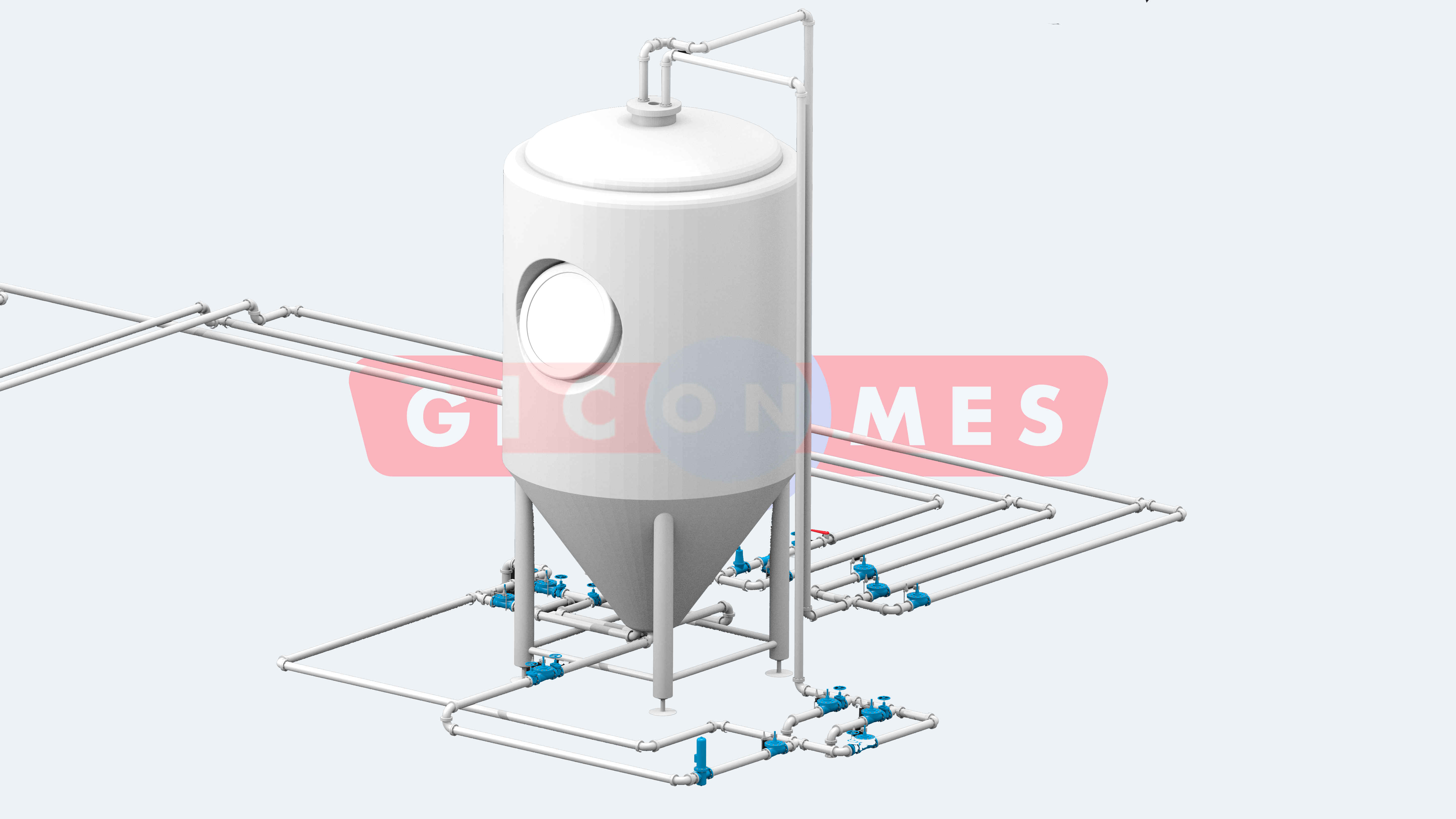

Condensate outlet of the fermenter:

– Thermodynamic purger

– Pneumatically actuated valves

– Check valve

500 liter fermenter

Calorifuged pipelines carrying steam

A common feature in these installations is the presence of calorifuged pipes that transport steam throughout the installations. These pipes are designed to maintain a constant and efficient temperature, avoiding heat losses and ensuring that the steam reaches its destination in ideal conditions.

In addition, key elements such as valves, boilers and filters are incorporated to ensure optimal system operation. These components are essential to control steam pressure and temperature, thus ensuring process safety and quality.

Facilities

In the pharmaceutical, food and biotechnology industries, efficiency and quality are essential to ensure the necessary quality standards.

A critical part of ensuring both efficiency and quality in industrial processes is the installation of highly specialized steam systems.

QUALITY FACILITIES

It is crucial to choose experts in specialized engineering

Proper choice of components and precise engineering are crucial in these installations, as high quality steam is essential for both product integrity and operational efficiency.

Sterilization, cooking and other thermal processes depend on the quality of the steam supplied. This not only affects productivity, but also ensures that pharmaceutical and food products meet the most stringent quality and safety standards.

Giconmes Technology FOR FACILITIES

Get to know Giconmes technology For installations

Or tell us about your industry’s facility needs and we’ll help you.

Are you interested in knowing in depth how the implementation of your fully customized installation will be done?

What type of installation do you need?

Here you will find a sustainable solution for standard industrial installations or tailored to your needs.

Giconmes has vast experience in the installation of AISI 304 and AISI 316 stainless steel steam systems, two of the most resistant and durable materials available in the industry.

This ensures corrosion resistance and long-term durability, which is essential to meet the hygiene and quality standards required in these industries.

In addition, the Giconmes team is trained to assist in the subsequent legalization of the installation, ensuring that it complies with all regulations and safety standards.

Steam and

Giconmes

Here you will find informative articles about steam technology, its application in industry, and different types of related equipment, as well as the latest trends and developments in this field.