Substrate desisfection with steam generators

What is a substrate?

Substrate is any solid material other than soil, whether natural, synthetic, residual, mineral or organic, which, when placed in a container alone or mixed, allows the anchoring of the plant’s root system and at the same time supports it and may even intervene in its mineral nutrition process.

In general, these materials, depending on their origin and application, have different compositions and granulometries and can be of organic origin (manure, agricultural by-products, peat, etc.) or inert (rock wool, perlite, vermiculite, sand, etc.). Sawdust, pine bark and vegetable compost known as leaf soil are also used.

The microorganisms potentially existing in the substrate, as well as any biological activity in it, compete with the development of the plant through the uptake of oxygen and nutrients, which is why we have to select a good material to configure it.

Its granulometry, porosity and bulk density should not be altered during cultivation, hence the importance of incorporating organic and inert materials in its composition. A good substrate depends on several factors: type of plant material, species, climatic conditions, irrigation, fertilization, etc., without forgetting the economic aspects.

Once these variables have been considered, it is necessary to make sure that there are no microorganisms or insects that could ruin the crop.

The imperative need to eliminate the aforementioned alterations is forcing technologists and technicians to identify the great variety of organisms that find favorable living conditions in the substrates. To this biotic phase belong bacteria, fungi, mycoplasmas, nematodes, arthropods, protozoa, mites, viruses, etc., pathogens that are antagonistic to plants in various stages of their development and that the favorable conditions for their development in greenhouses allow their multiplication when the substrates are not disinfected.

Substrate treatments aimed at combating microfauna, macro or microflora, are usually referred to as disinfectant treatments and have historically been carried out by applying fumigant substances or solutions.

Saturated vapor as an alternative to methyl bromide

The use of saturated steam has replaced the use of methyl bromide in the sterilization of substrates in many developed countries. Steam is a feasible and proven alternative to this chemical compound to control pests and diseases, here’s why:

Methyl bromide

The widespread use of chemicals in the preparation of soils and substrates used in greenhouses over the years is the origin of a series of problematic alterations that affect human health and soil sustainability.

Methyl bromide (98% MeBr) mixed with Chloropicrin (2% Pic) or a similar alternative product has been used since 1940 for the fumigation of substrates intended for high value agricultural crops to control phytosanitary problems generated by insects, nematodes, pathogens and weeds, generally.

This gas, which can contaminate groundwater, has been identified as an ozone depleting gas. and is included in the Montreal Protocol on Substances that Deplete the Ozone LayerThe Montreal Protocol, known as the Montreal Protocol, sponsored by the United Nations and signed by the vast majority of developed countries as the great enemy of the environment.

In addition, its vapors cause skin damage, including burns, are toxic to humans due to their high bromine content and can cause cancer.

This situation has reoriented the productive agricultural systems towards cleaner techniques, leaving these chemical compounds aside and identifying the application of saturated steam as a globally accepted alternative to methyl bromide.

Steam application in intensive agriculture and the DFTerm® concept

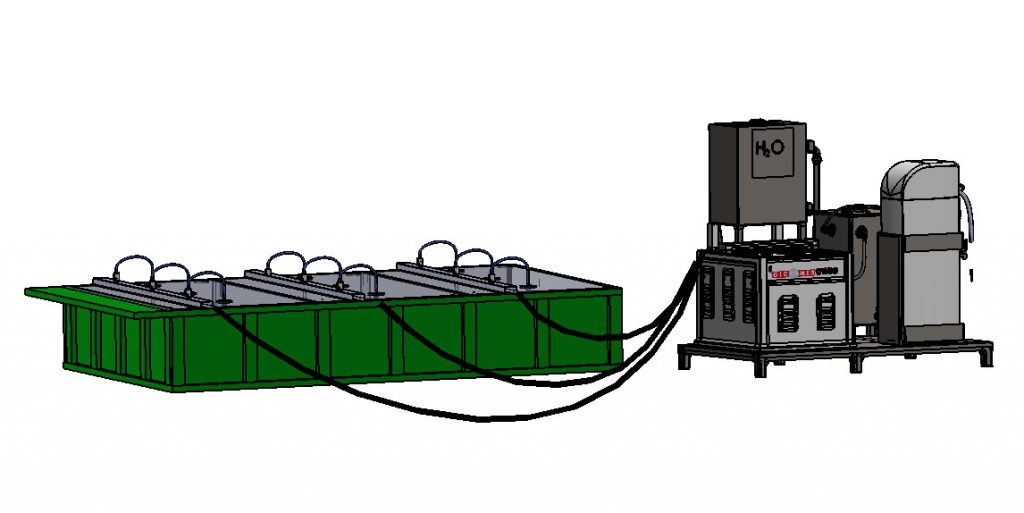

This is a technique developed by GICONMES IBERICA for disinfection/sterilization/pasteurization, based on the application to the substrate of heat transmitted by steam applied with equipment developed for this purpose.

The application of Physical Disinfectionby ThermalControl(DFTerm®) increases the temperature of the substrate and simultaneously that of the living organisms that inhabit it for a certain period of time. The installed pathogens die once the vital thermal point of each of them has been reached.

DFTerm® can be applied in static or dynamic operation prior to the seeding process by synchronizing speed, time and temperature parameters in confined spaces and without the need for high power steam generators.

The DFTerm® application is ecological, effective and efficient for all types of substrates, especially those used in greenhouses equipped with state-of-the-art technology such as aeroponics and hydroponics.

Steam disinfection of substrates is a health-friendly and totally ecological technique used in intensive and high value-added agriculture , especially in vegetable and ornamental greenhouses to eliminate pathogens (fungi, bacteria, nematodes) and weed seeds usually present in soils and substrates.

It is a totally feasible alternative to methyl bromide and has been tested in different processes for the control of pests and diseases. According to the Methyl Bromide Technical Options Committee (MBTOC), a group of experts belonging to the United Nations Environmental Program (UNEP) responsible for the control and application of methyl bromide, steam has replaced its use in the sterilization of substrates in most developed countries, with widespread application of steam expected before 2030.

Principle of application

The steam application is performed at low atmospheric or sub atmospheric pressure with a substrate moisture content between 15 and 20% prior to the operation. More humidity or saturation reduces the efficiency of the process because the water fills the macropores of the substrate, preventing adequate heat diffusion and generating excess condensation.

Regarding the temperature, it is not advisable to exceed 110ºC, since at this temperature beneficial organisms for the soil are destroyed. The optimum steam application is between 30 and 50 kg steam/m3 of substrate and its distribution through the substrate is done using the pressure generated in the boiler for steam generation. A suction effect is recommended to control potential excess humidity.

It is also advisable to have a protected space for storing and airing the treated substrate, and it is advisable not to use it until 48 hours have elapsed. The use of steam application because the accumulation of nitrogen in the form of ammonia from the decomposition of organic matter can be toxic to seeds and plants.

Operating procedure

The effective elimination of pathogenic microorganisms recommends a temperature between 80 and 110ºC in the disinfection chamber for a period of time ranging from 15 to 60 minutes, always depending on the density, degree of initial humidity and typical causative agents to be eliminated.

The substrate should be as dry as possible, in such a way that when you take a handful and squeeze it with your hand, you will feel a slight humidity in the palm of your hand. If it releases water or stains our hand, we have to consider the excess of humidity and act accordingly. The disinfection chamber should be as airtight as possible in order to maintain the temperature. As a reference, in practice, if the aim is to eliminate weeds, fungi, insects and nematodes by steam application, the following temperatures should be applied:

- 100ºC – 90ºC : Weeds and heat resistant viruses are eliminated.

- 80ºC – 70ºC : Weed seeds, all phytopathogenic bacteria and most plant viruses are eliminated.

- 70ºC – 50ºC : Most phytopathogenic bacteria, worms, slugs, white root rot, filamentous fungi, gray and white mold, adelomycetes and nematodes are eliminated.

Thermophilic bacteria, present in most substrates, should be identified in order to subject the substrate to the appropriate temperature.

Sterilization, disinfection or pasteurization?

By means of a sterilization process we eliminate all forms of microbial life such as viruses, bacteria, fungi, protozoa, spores, etc. and logically has a relatively high cost compared to complementary processes such as disinfection, which eliminates only pathogens.or pasteurized which is sufficient when we try to eliminate some bacteria, molds or fungi. In addition, we have to take into account that the total elimination of microorganisms can negatively affect the subsequent development of the varieties to be cultivated.

The option to be used, exposure times, temperature, etc., depend on considerable variables. Among them:

- Composition of the raw material used in the composition of the substrates

- Density

- Bacterial load and typology

- Humidity level

- Machining level of the installation

- Environmental asepsis level

- External incubation parameters

- Intrinsic characteristics of each species to be cultivated ……

It is not easy to define a priori which option to use, nor to define the optimum temperature or the appropriate exposure time. It should be kept in mind that microorganisms die at a constant rate; if the mortality curve is plotted logarithmically, the rate of disappearance of microorganisms is constant.

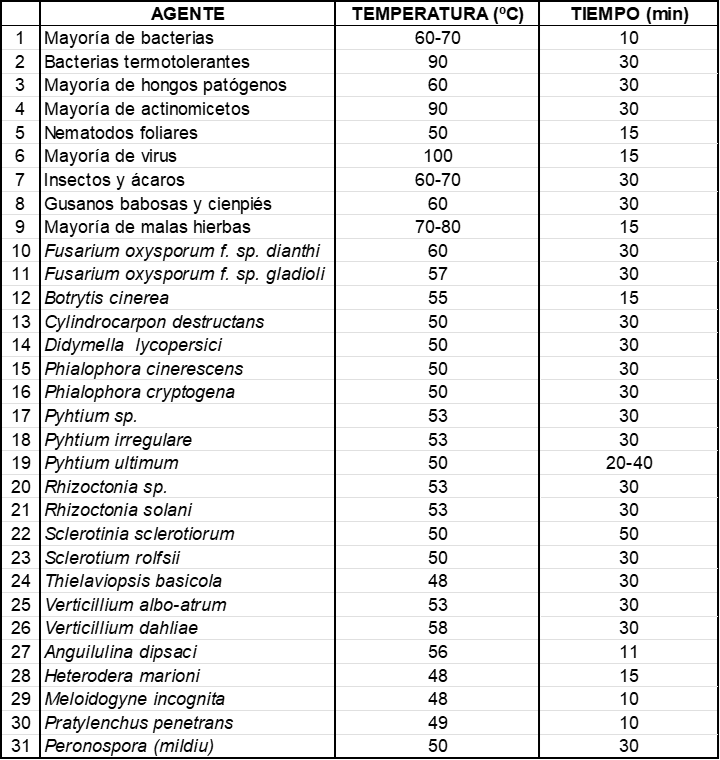

Temperature and theoretical exposure time to vapor for various causative agents

Are you interested in applying thermal disinfection to substrates?

If you wish to obtain more information about the application of the DFTerm® technique for the physical disinfection of substrates, we recommend that you contact with GICONMES IBERICA through this form or directly to the phone number: +34 976 50 01 08

# fungicide to disinfect the soil

# agricultural soil disinfection

# how to disinfect the soil

# how to disinfect the soil in a natural way

# how to disinfect agricultural soil