Steam for Heating, Food, Clean Steam, and Pure Steam

Steam is primarily used for heating, sterilizing, and sanitizing.

It offers endless possibilities of application, always related to heating, sterilization, and sanitization.

In hospitals, steam is commonly used to sterilize medical instruments. In the industrial sector, it is used as a heat source or to sanitize surfaces, conveyors, machinery, and other elements. The energy sector utilizes the heat energy of steam to drive turbines and generate electricity.

Steam for Heating

Heating for efficient heat transfer.

The application of saturated steam for heating allows precise temperature control by regulating the steam pressure. When the steam condenses in the heat exchanger, it becomes saturated water at the same temperature as the saturated steam, facilitating immediate and efficient heat transfer. By maintaining a constant pressure, rapid, continuous, and uniform heating can be achieved at all transfer points.

- Maximum heat transfer capacity.

- Condensation heating.

- Fast and uniform heating.

- Enables heating with green steam (powered by renewable energy)

Steam for Sterilization

Sterilization to eliminate bacteria and pathogens.

High-temperature steam is considered one of the most effective sterilizing agents as it coagulates the proteins of microorganisms, denaturing them and causing rapid death. Sterilization, as an absolute condition, can only be expressed as a mathematical probability. Microbial destruction by steam follows an exponential law, and achieving complete sterility would require an infinitely long process. Since analyzing each product individually is impractical, we measure effectiveness through the validation of machines and processes. Sterilization is a complex process that sometimes incurs significant costs that need to be carefully considered beforehand. The autoclave, in its broadest sense, is the most reliable and widely used equipment for sterilization, capable of eliminating viruses and spores.

- Temperature above 100°C.

- Precise control of steam/air concentration.

- Detailed control of pressure, time, and temperature.

- Creation of vacuum as per requirements.

Steam for Sanitization/Disinfection

Environment sanitization and disinfection

Sanitization and Disinfection of Environments We refer to these processes as smaller in scale compared to sterilization. Dust mites, fungi, germs, and bacteria in their vegetative forms can be easily eliminated at a temperature of 100°C for a few seconds. By heating surfaces to this temperature (pasteurization), we achieve the destruction of the vast majority of pathogenic microorganisms in their common vegetative forms found in machines and utensils used in the processing of various types of food. These applications are also effective in everyday life activities.

- Eliminates the majority of pathogenic microorganisms.

- Reduces chemical usage and water consumption by up to 80%.

- Creates a healthy and safe environment.

- Wide range of applications.

Illustrative Applications

- Heat Transfer: Thermodynamics serving the thermal gradient

- Cleanliness: Sanitization, disinfection, and sterilization

- Scalable steam purity according to the applications: The purer the steam, the more demanding the process becomes. What do you need?

- Reduction of CO2 emissions: Minimization of carbon footprint through maximum efficiency.

- Electrical Efficiency: Electric equipment up to 30% more efficient than fossil fuel-powered alternatives.

- Automation: Operational efficiency is at the core of our activity.

- Purging, Condensate, and Energy Recovery: We utilize what others waste in our projects.

- Turnkey Projects: We take care of everything: execution, communication, maintenance, and a comprehensive solution.

- Humidification: Air heating through convection.

- Control and Peripherals: What is not controlled cannot be measured, and what is not measured cannot be optimized.

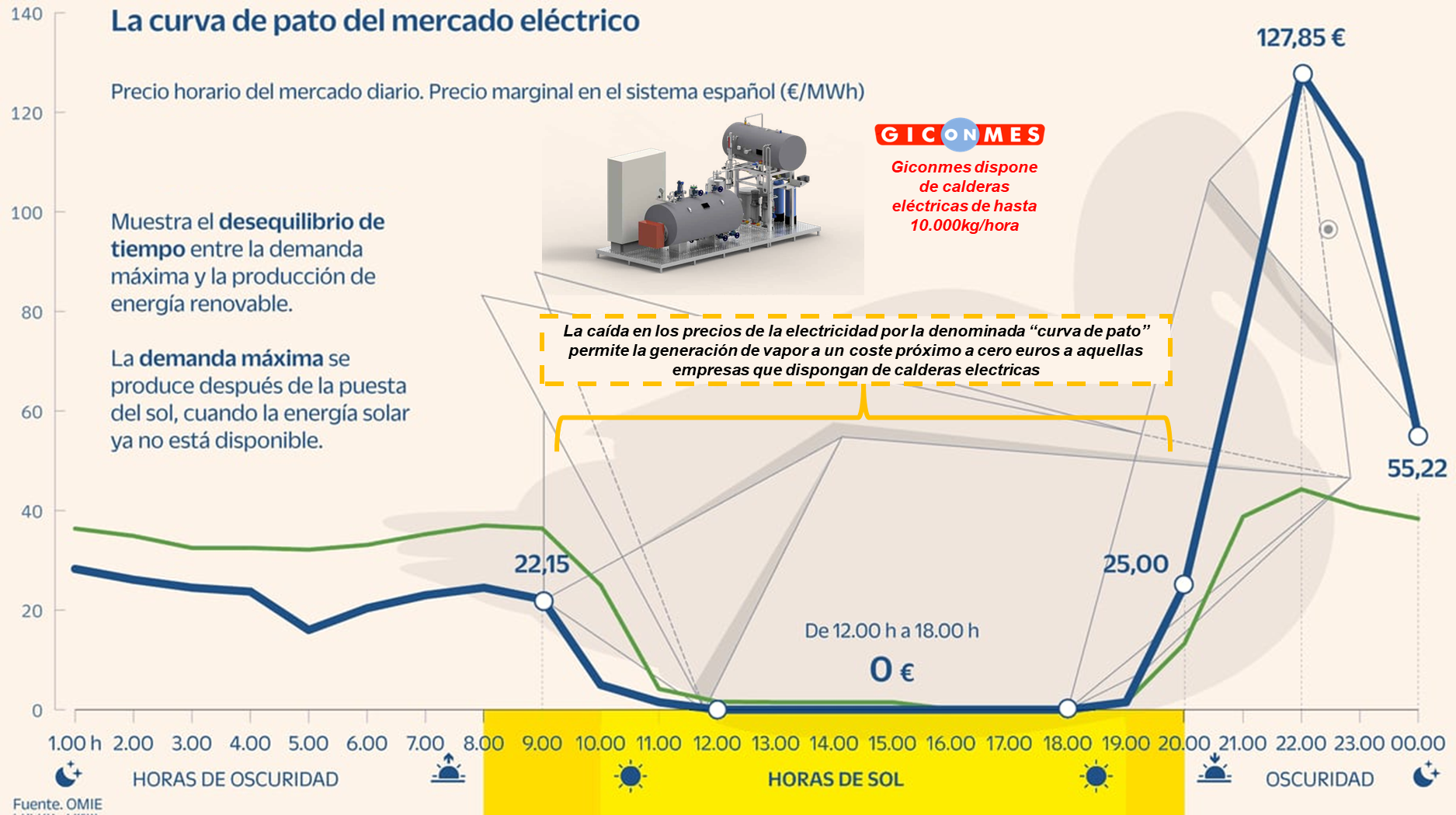

- Power-to-X Solutions: Conversion of renewable electricity into energy for fuel, chemicals, ammonia, etc.

- Substrate Regeneration: No more methyl bromide!

Types of Steam based on Purity

Description:

Steam is produced by a conventional generator with an unspecified steel boiler. Usually, only the mechanical properties of the steels are considered, ignoring their chemical composition.

Water Treatment

: Must comply with the specifications in EN 12952

Purity:

Not considered clean steam. May be contaminated with particles from the water network.

Uses:

- Indirect uses: tank with heating jacket, heat exchanger, coil, vacuum, etc.

- Direct uses: power, impulse, atomization, cleaning, hydration, humidification, etc.

Risks:

- Possible chemical or biological contamination.

- Contamination by rust or other particles.

- Not suitable for contact with medical products, food, cosmetics, etc.

Regulation:

- RD 2060/2008 and RD 709/2015

- Directive 2014/68/EU

Description:

Also known as culinary steam. Produced by a steam generator with a heating body made of stainless steel and filtered to ≤ 5μ.

Water Treatment:

Must comply with the specifications in EN 12952 and ISO 9963. Osmotization is recommended.

Purity:

The taste and color of food are influenced by the purity of the steam used in the process.

Good manufacturing practices for all equipment involved in the industry should be considered.

Uses:

- Description: Can be used directly or indirectly with food

products. - Do not use in direct contact with medications.

Risks:

- There may be risks of cross-contamination.

Regulation:

- CE Regulation 1935/2004

- CE Regulation 852/2004 (Chapter VII, Section 5).

- RD 902/2018

Description:

Steam of superior quality, filtered, and free from contaminants. Produced by a generator made entirely of stainless steel (boiler and pipes) and fed with water that has undergone reverse osmosis.

- Water Treatment:

Deminerized and filtered water through reverse osmosis. - Water with low conductivity.

- Must be maintained in an aseptic atmosphere in a cold circuit.

Purity

Clean steam without any relevant contamination.

Uses:

- Sterilization

- Cosmetic applications

- In situ sterilization (SIP)

- Humidification of air in clean rooms and operating theaters.

Risks:

- As there are no additives in the water, there is no risk of chemical contamination.

Regulation:

- CE Regulation 1935/2004

- CE Regulation 852/2004 (Chapter VII, Section 5)

- Directive 2014/68/EU

- Health Technical Memorandum (HTM) 2010; 2021, EN 285, EN 554

Description:

Pure steam is obtained from highly purified water (HPW) Heat exchangers with double tube sheets are used to evaporate the purified water. The generators are made of austenitic stainless steel. Hygienic connections are used.

Water Treatment:

Highly purified water obtained through ultrafiltration.

Purity:

Extra-clean and uncontaminated steam.

Uses:

- Water for Injection (WFI)

- Injection of solvents, transfusions, or other pharmaceutical products

- In situ sterilization (SIP)

- Biotechnology

Risks:

N/A

Regulation:

- HTM 2031, EN 285

- European Medicines Agency (EMA)

- European Pharmacopoeia (Ph. Eur)

- United States Pharmacopeia (USP)

- Japanese Pharmacopoeia (JP)

Do you have any doubts to solve? Our team of professionals is here to assist you

Steam and

Giconmes

Here you will find informative articles about steam technology, its application in industry, and different types of related equipment, as well as the latest trends and developments in this field.