Electric Steam Generators

Main features of electric generators:

An electric boiler is a type of pressure vessel in which the energy transfer for steam generation is achieved through electric resistances.

These resistances, immersed in the liquid phase of the fluid, transfer all the heat energy, resulting in optimal thermal efficiency.

Electric boilers do not emit pollutants into the atmosphere and, therefore, do not require a chimney for the release of combustion gases.

They also don’t require fuel storage tanks with supply lines, only an electrical connection.

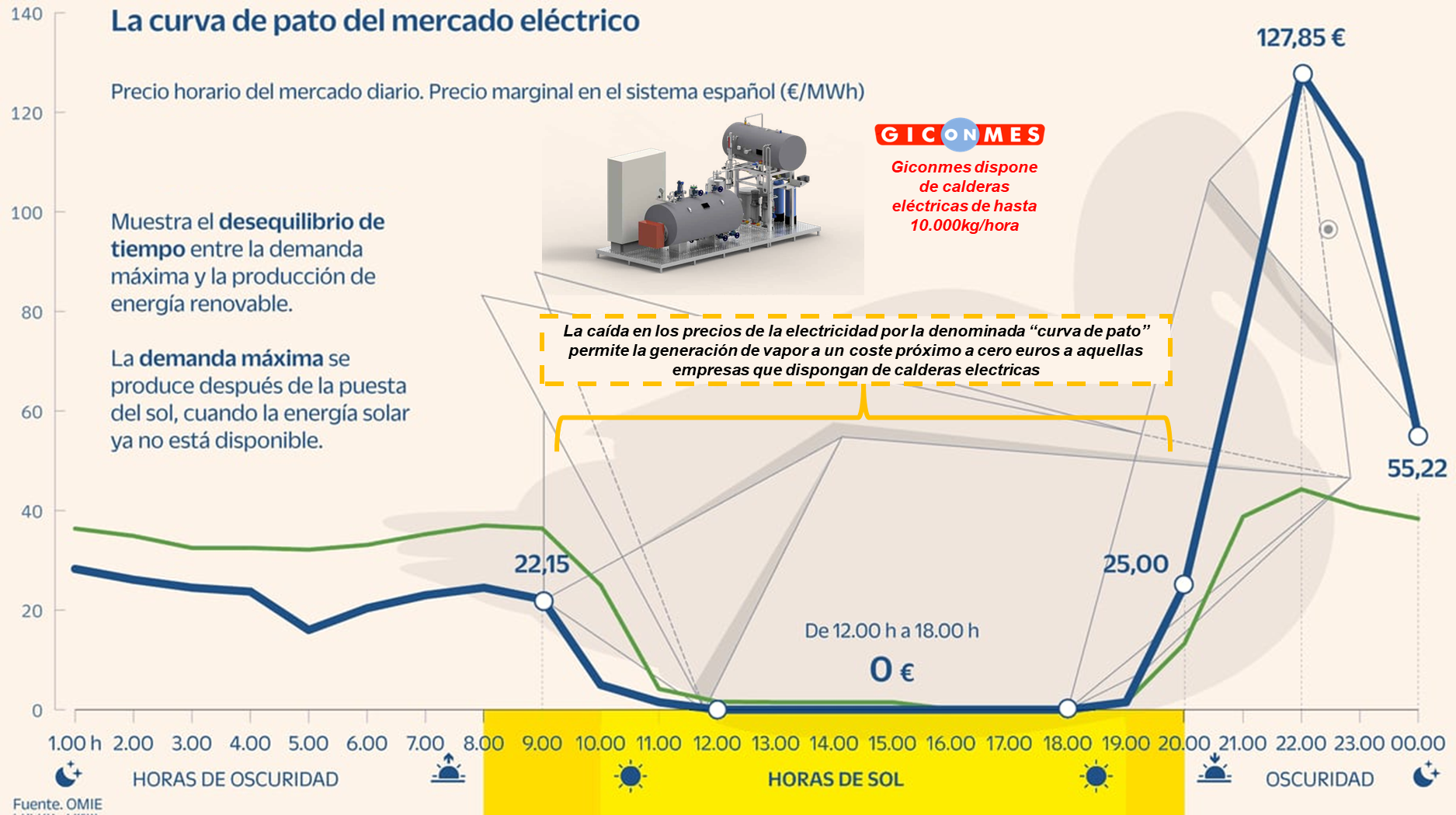

The use of renewable energy sources directly contributes to reducing environmental impact, making it a realistic goal to achieve complete elimination of emissions, thus turning the installation into a neutral or “net zero” system.

Some advantages of our electric steam generators

compared to other steam production methods are as follows:

Eficiencia:

Even at low utilization levels, the electric alternative is more efficient than fossil fuels, allowing for smaller installation dimensions for the same generation capacity.

Emisión cero de gases contaminantes:

It is neutral in direct emissions and has the potential to be 100% clean through the use of renewable energy.

Seguridad:

There is no combustion, smoke emission, or other gases. It also does not require a specialist to operate or a boiler room.

Coste de mantenimiento:

Structural and mechanical simplicity allows for streamlined and cost-effective maintenance.

Potencia incremental en función de necesidades (modularidad):

Possibility to configure a generator with multiple independent power options.

Simplificación de la instalación:

Possibility of installing the electric boiler near the point of steam application, reducing installation costs and inefficiencies in pressure and temperature.

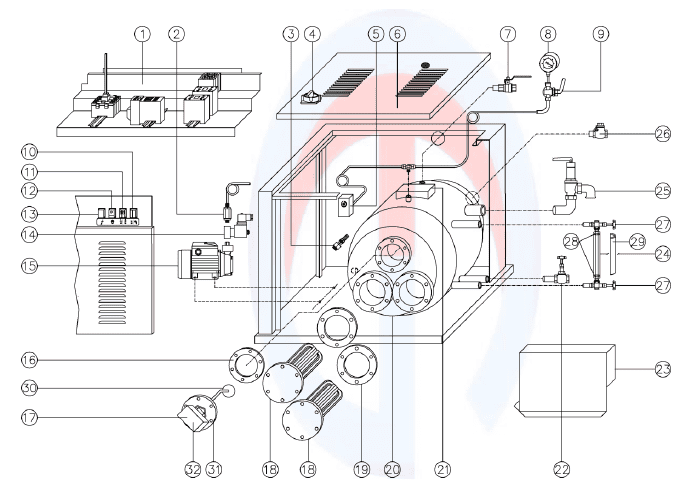

Essential components of an electric steam generator:

Each component performs a specific function in an industrial steam generator, contributing to efficient and safe operation.

1 Bottom panel

2 Check valve

3 Rubber holder 3/8″ M – Ø12

4 Isolating switch

5 Pressure switch 2 ÷ 5.5 bar

6 Upper panel

7 Ball valve 1/2″

8 Pressure gauge

9 1/4″ valve for pressure gauge

10 Water feed pilot

11 First resistance switch

12 Boiler switch

13 Voltage presence pilot

14 Complete solenoid valve 230V 50/60Hz

15 Pump PQ81 230/400V – 50Hz – 3Ph

16 Level control gasket

17 Complete automatic level control

18 Boiler resistance 6 ÷ 30 kW

19 Resistance gasket

20 Certified boiler PED

21PED card Boiler

22 drain valve

23 Resistance protection cover

24 Level glass

25 Safety valve 1″ – Pilot for boiler resistance Level valve – Clapet 1/2″

27 Level control valve pair – Second resistance switch

28 Level glass gasket

29 Level glass protection

30 Float level control

31 Level control plate

32 Ampoule for PQM81 pump 230V – 50Hz – 1Ph

Do you have any doubts to solve? Our team of professionals is here to assist you

Steam and

Giconmes

Here you will find informative articles about steam technology, its application in industry, and different types of related equipment, as well as the latest trends and developments in this field.