Success stories

Steam installation in a canning industry

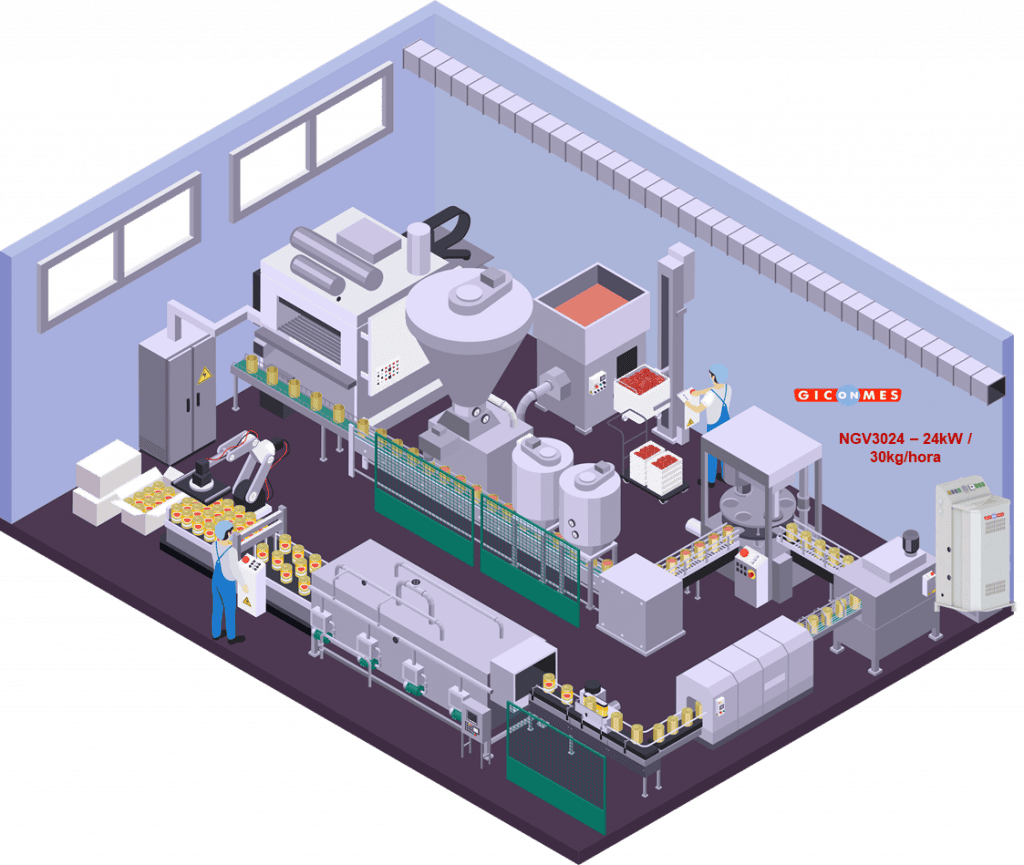

Project Description

Installation of a 30kW equipment manufactured with all components in contact with water in AISI 304 stainless steel to ensure correct operation of the bottling stage.

Original situation:

Challenges posed by the client:

Necessity to feed steam at 180ºC to the canning can sealing machine. The main objectives are as follows:

Steam sterilization: Hot steam is used to sterilize both jars and lids before sealing. This helps to eliminate any bacteria or microorganisms present inside the container, which helps to prolong the shelf life of the packaged product.

Hermetic sealing: Steam is also used to create an airtight seal between the lid and the canister. When the canister is heated with steam, the air inside expands and escapes, creating a vacuum as the steam cools and condenses. This helps to keep the contents of the jar fresh and protected from external contamination.

Proposed solution:

Customized steam solution developed by Giconmes.

Proposed solution:

We installed a 30 liter boiler with a 22kW configuration to generate up to 30kg/hour of dry steam to feed the production line. The requirements of the food industry made it necessary for steam generators to be manufactured with all components in contact with water made of stainless steel. With this installation, the customer is assured of a hermetic seal for all processed cans.

The following is the detail of the closing process and the performance of the steam:

- Air removal: before closing the canister, steam is used to heat the contents and the air inside the canister. When the air is heated, it expands and leaves the canister. This process helps to remove oxygen from inside the package, which is crucial to avoid food oxidation and prevent the growth of aerobic microorganisms that could cause spoilage or contamination.

- Vacuum creation: once the canister has been filled and the air has been removed, the airtight lid is placed over the mouth of the canister. The assembly is then subjected to gradual cooling, which causes condensation of the steam inside. As the steam cools, it creates a partial vacuum inside the canister, as the space occupied by the steam is reduced. This vacuum is essential as it helps to create a negative pressure inside the container, which forces the lid down and ensures an airtight seal.

- Secure sealing: once the steam has condensed and a vacuum has been created, the lid seals tightly to the canister. This hermetic seal prevents air from entering and contents from escaping, which helps to maintain the freshness of the packaged product and prevent contamination by external microorganisms.

Technology used:

A steam generator

- Boiler NGV 3024 of 30kW manufactured with all components in AISI-304 and safety valve at 8.5 bar.

Do you need a customized solution?

We help you define what type of installation you need

FAQs

We understand that many questions may arise. Here are some of the most common ones.

There are no emissions beyond those produced during the electricity production process. Consequently, emissions can be neutral depending on the electricity mix. Electric steam boilers are the present and the future.

Absolutely. In fact, it is recommended to achieve maximum efficiency. There is no problem with remote control as long as it complies with current regulations.

A steam generator is a pressure vessel that, together with the piping network, is subject to regulatory control and complementary technical instructions, according to the regulations published in Royal Decree 809/2021, of September 21. Maintenance is divided into a part that can be easily fulfilled by the owner:

- Know and apply the manufacturer’s instructions regarding use, safety measures, and maintenance.

- Not to put the installation into service or prevent the operation of pressure equipment if the requirements of the Regulation are not met.

- Having at least the following documentation for the pressure equipment while they are installed: Declaration of conformity, manufacturer’s instructions (if applicable), and, if necessary, installation certificate, along with other supporting documentation (such as installation project, record of the last periodic inspection, certifications of equipment repairs or modifications, and any other documentation required by the relevant technical instruction complementary to this regulation). For detailed contents, refer to Annex IV of the regulation. Making this documentation available to the competent authority of the autonomous community and the companies responsible for maintenance, repair, or periodic inspections.

- Use the pressure equipment within its intended operating limits as specified by the manufacturer and take it out of service if it no longer meets the necessary safety requirements.

- Perform maintenance on the installations, pressure equipment, safety accessories, and control devices in accordance with the operating conditions and manufacturer’s instructions, and examine them at least once a year.

- Arranging for the necessary periodic inspections as required by Article 6 of the regulation.

- Having and maintaining an up-to-date record of pressure equipment categories I to IV, as defined in RD 709/2015, of July 24, or equipment similar to these categories according to Article 3.2 of the regulation, as well as their installations.

It is known that by applying heat to water, it transforms into steam at the boiling point and atmospheric pressure. From there, depending on the required saturation degree of steam for its proper application, we need to increase the pressure to obtain a higher temperature. To change the temperature and saturation degree of steam, we always need to modify the pressure.

It is a unit of pressure equivalent to 1 kg/cm2, 0.98 atmospheres, or 14.50 PSI.

Haven't found the answers to your questions?

Please send us a question or download all the information

USES OF STEAM IN INDUSTRY AND OTHER BUSINESSES

Other similar success stories using steam

The use of steam is gaining popularity in various industries due to its effectiveness and environmental benefits..

In our "Success Stories" section, you can discover more about companies that have adopted this technology and have achieved successful results in terms of efficiency and sustainability. Click on the success stories to learn more details.