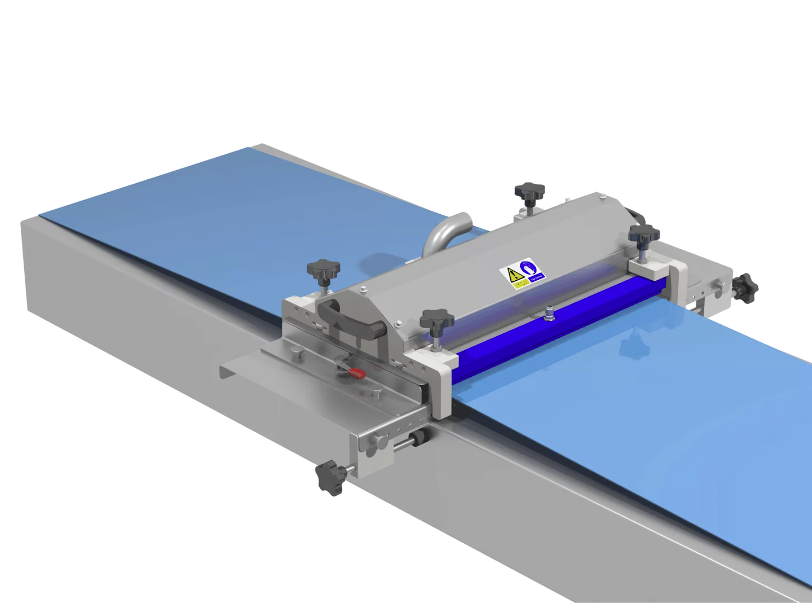

Brush Conveyor Features

The Brush system incorporates multiple brushes inside to remove coarse residue. It is designed to efficiently clean conveyor belts in various industrial environments. This system provides an effective and portable solution to maintain optimal cleanliness and hygiene when the Brushless system is not sufficient.

The system includes a series of rotating brushes that effectively clean the surface of the belt, ensuring thorough cleaning and preventing residue buildup.

One of the main advantages of this system is its portability. Its compact and lightweight design allows for easy maneuverability and quick installation on conveyors of various sizes

| Model | Brush |

| Voltage (VDC) | 24 |

| Conveyor width (mm) | Practically any size starting from 300 mm. |

| Variable speed (mm/s) | 0-1500 mm per second (approx.) |

| Weight (kg) | 19.5 kg for the 1150 mm model. |

| Steam hoses | Silicone-insulated, made of stainless steel with reinforced high-temperature PTFE |

Advantages of Brush Cleaning Conveyors

- Increases productivity of manufacturing lines.

- Savings in maintenance and labor costs.

- Frees up cleaning and maintenance personnel.

- Improves sanitation levels by eliminating bacteria, molds, and other microorganisms.

- Increases the lifespan of the conveyors.

- Enhanced customer perception.

Brushless compatible steam boilers

FAQs

We understand that many questions may arise. Here are some of the most common ones.

There are no emissions other than those produced in the electricity production process. Therefore, they can be neutral depending on the electricity mix. Electric steam boilers are the present and the future.

Absolutely. In fact, it is recommended to achieve maximum efficiency. There is no problem with remote control as long as current regulations are followed.

A steam generator is a pressure vessel that, along with the pipe network it is connected to, is subject to regulatory control and complementary technical instructions, according to the regulations published in Royal Decree 809/2021, dated September 21st. Its maintenance is divided into a part that can be easily performed by the owner:

- Familiarize yourself with and apply the manufacturer’s instructions regarding the use, safety measures, and maintenance

- Do not put the installation into operation or prevent the operation of pressure equipment if the requirements of the regulations are not met.

- It is necessary to have, at least, the following documentation of the pressure equipment while they are installed: Declaration of Conformity, if applicable, manufacturer’s instructions, and, if necessary, installation certificate, along with other supporting documentation (such as Installation Project, record of the last periodic inspection, certifications of equipment repairs or modifications, as well as any other documentation required by the corresponding complementary technical instruction (ITC) of this regulation). For detailed information, please refer to Annex IV of the regulation. This documentation should be made available to the competent authority of the autonomous community and to the companies that carry out maintenance, repairs, or periodic inspections.

- Use the pressure equipment within the intended operating limits specified by the manufacturer, and remove them from service if they no longer meet the necessary safety requirements.

- Perform maintenance on the installations, pressure equipment, safety accessories, and control devices in accordance with the operating conditions and manufacturer’s instructions, and examine them at least once a year.

- Arrange for the necessary periodic inspections as stipulated in Article 6 of the regulation.

- Maintain an up-to-date record of pressure equipment belonging to categories I to IV, as defined in RD 709/2015, dated July 24th, or equipment deemed equivalent to these categories according to Article 3.2 of the regulation, as well as their installations.

It is known that by applying heat to water, it transforms into steam at its boiling point under atmospheric pressure. From there, depending on the desired level of steam saturation for its proper application, we may need to increase the pressure in order to achieve higher temperature. To change the temperature and saturation level of steam, we always need to modify the pressure.

A bar is a unit of pressure equivalent to 1 kg/cm2, 0.98 atmospheres, or 14.50 PSI.

Haven't found the answers to your questions?

Please send us a question or download all the information

Quick technical service, with trained professionals and service plans focused on your company

What kind of steam system do you need?

Equipment rental

Reliable, safe equipment with a 5-year warranty.

Enjoy the security of a personalized service

24/7 adapted to your needs.

Do you need a customized solution?

We help you define what type of installation you need

Steam and

Giconmes

Here you will find informative articles about steam technology, its application in industry, and different types of related equipment, as well as the latest trends and developments in this field.